CNC Stepper Gantry

A CNC stepper gantry is a highly efficient and versatile solution for precise and automated motion control in manufacturing and engineering applications. Powered by stepper motors, this system ensures exceptional accuracy and smooth motion, enabling intricate operations like cutting, engraving, and 3D printing. A stepper motor gantry excels in automation, simplifying complex tasks by delivering repeatable precision while reducing manual intervention. Its modular design and compatibility with various tools make a CNC stepper gantry ideal for industries such as aerospace, automotive, and prototyping.

The robust construction of a stepper gantry system ensures durability, allowing it to perform flawlessly over extended periods. By integrating this advanced technology, businesses can significantly enhance productivity, achieve superior quality, and streamline operations, making it a game-changer in modern manufacturing and fabrication processes.

Travel: 12”x8”x3.5” or 16”x12”x 5.5”

LOWCOST complete system

A ready-to-use stepper motor cartesian robot or CNC system - WIRED, with PAL software

Ball screws on all 3 axes - for smooth, playfree motion that never needs adjustment

Fully assembled, available with or without electronics in a CE compliant safety enclosure.

The ICP electronics uses either CNC or DNC programming via RS232.

Comes equipped with a saftey interlock so the machine cannot be opened while it is running and a program cannot be started while the door is open.

It is also avaiable with servos. Please see our ICV cartesian robot.

The robust construction of a stepper gantry system ensures durability, allowing it to perform flawlessly over extended periods. By integrating this advanced technology, businesses can significantly enhance productivity, achieve superior quality, and streamline operations, making it a game-changer in modern manufacturing and fabrication processes.

Travel: 12”x8”x3.5” or 16”x12”x 5.5”

LOWCOST complete system

A ready-to-use stepper motor cartesian robot or CNC system - WIRED, with PAL software

Ball screws on all 3 axes - for smooth, playfree motion that never needs adjustment

Fully assembled, available with or without electronics in a CE compliant safety enclosure.

The ICP electronics uses either CNC or DNC programming via RS232.

Comes equipped with a saftey interlock so the machine cannot be opened while it is running and a program cannot be started while the door is open.

It is also avaiable with servos. Please see our ICV cartesian robot.

Configure Your Part

Select Options then Click “Add to Quote”

Part Number:

|

| Add To Quote |

| ICP 4030 | |

| ICP 4030 | |

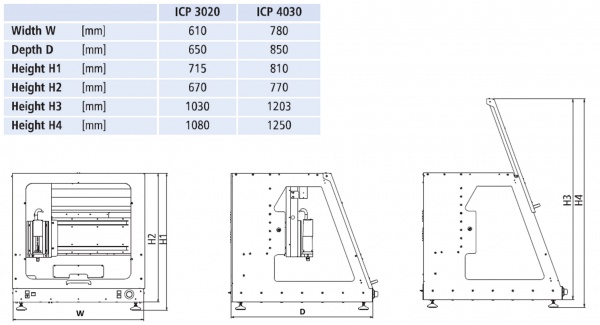

| Traverse path X/Y/Z [mm] | 400 x 300 x 140 |

| Clamping table surface W × D [mm] | 700 x 375 |

| Throughput [mm] | 170 |

| Dimensions W × D × H [mm] | 780 x 850 x 810 |

| Guides | Linear units with precision steel shafts and recirculating ball slots, clearance free adjustable |

| Process speed X/Y/Z [mm/s] | 100 (for Ball screw drives 16x10) 60 (for Ball screw drives 16x4) |

| Repeatability [mm/s] | ± 0.02 |

| Drive motors | Stepper motors |

| Drive elements X/Y/Z | Ball screw drives 16 x 10 / 16 x 10 / 16 x 4 mm Clearance free adjustable (optional: 16 x 4 mm in X/Y/Z) |

| Controller | iMC-P step controller with 4 final stages 48V/4.2A and 500W power supply unit with processor board |

| Operation | Function keys and emergency shutdown |

| Software | WinRemote (optional: ProNC, isy CAM 2.8) |

| Weight [kg] | appr. 120 |

| Part-no.: | 280220 7405 * |