Flatcom Flatbed Automation System

Flatcom Series machines are a general automation platform.

Applications include:

Inspection, welding, milling, pick and place, dispensing, assembly,

- They come complete with mechanics, motors, controls, cabling, a stand and safety enclosure with either a safety interlock or optional light curtain.

- Travels range from 710mm x 750mm to 1210mm x 1250mm on the M Series.

- Travels on the L Series are 1500mm x 1700mm and 2500mm x 1700mm.

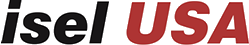

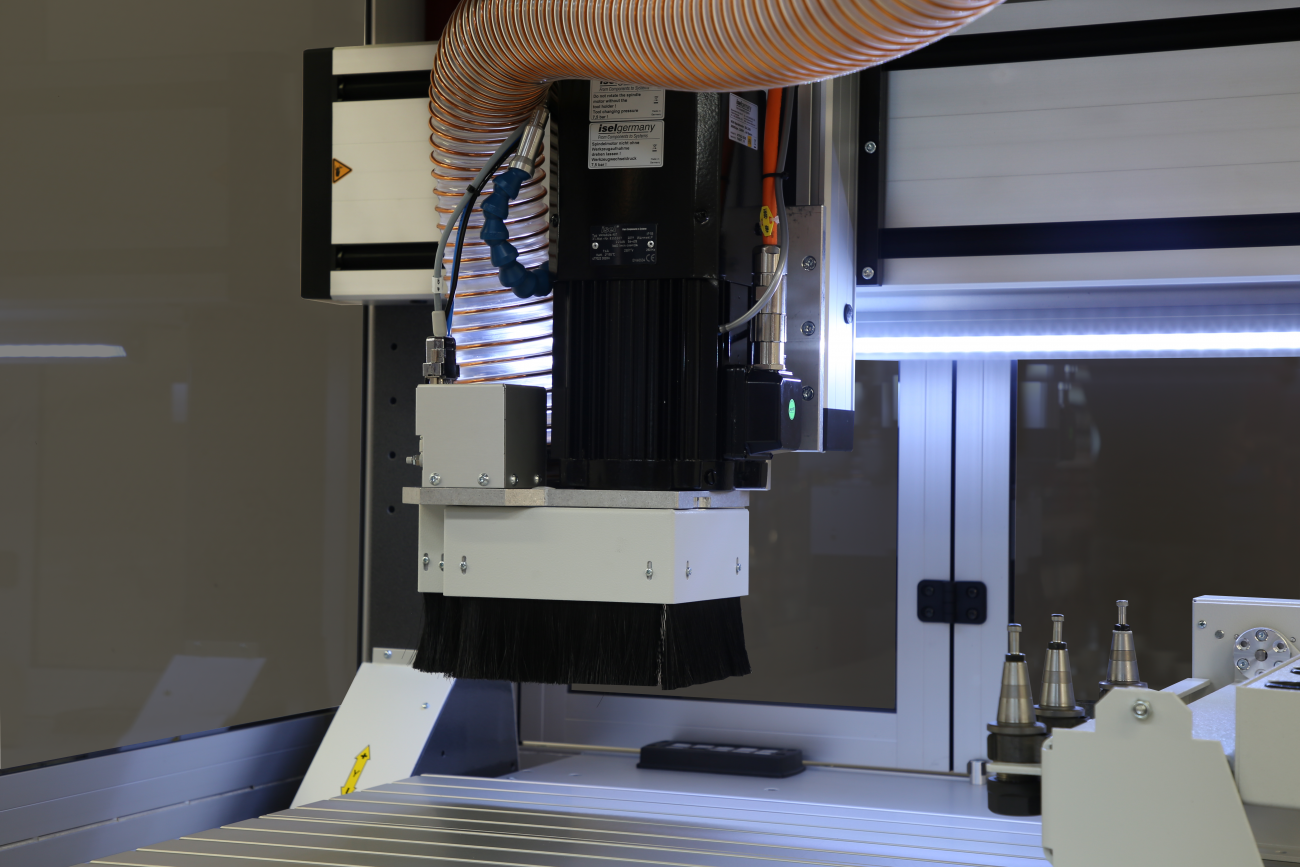

- Available in XY, XYZ. Standard machines come with 3 axis but can be custom built to include up to 5 axis.

- Flatcoms include electronics all wired in an industrial cabinet as well as an IPC25 industrial embedded PC with WIN 10. There is a swing arm that houses a flatpanel touch screen with keyboard and mouse.

- Gantry clearances of 250mm and 350mm on the M Series

- Gantry clearances of 270, 370 and 470mm on the L Series

- Z axis travel can be 210 or 310mm on the M Series.

- Z axis travel can be 210, 310 or 410 on the L Series

- Available without electronics for OEM applications

Applications include:

Inspection, welding, milling, pick and place, dispensing, assembly,

Configure Your Part

Select Options then Click “Add to Quote”

Part Number:

|

| Add To Quote |

| FLATCOM M Series | ||||

| Flatcom M20 | Flatcom M30 | Flatcom M40 | Flatcom M50 | |

| Processing areas X/Y [mm] * | 710 / 500 | 710 / 750 | 1,210 / 750 | 1,210 / 1,250 |

| Z lift [mm] | 210 (optional 310, in each case without processing unit) | |||

| Bench clamping area W x D [mm] | 800 x 750 | 800 x 1,000 | 1,300 x 1,000 | 1,300 x 1,500 |

| Z gap [mm] * | 250 (optional 350,in each case without processing unit) | |||

| Dimensions WxDxH [mm] | 1,275 x1,175 x1,920 | 1,275 x1,475 x1,920 | 1,775 x1,475 x1,920 | 1,775 x1,975 x1,920 |

| Processing speed X/Y/Z max. | 250 mm/s | |||

| Repeat accuracy [mm] | ± 0.02 | |||

| Drive motors | Servo motors | |||

| Drive elements X/Y/Z | Recirculating ball drive, adjustable for no play | |||

| Controller | iMD CAN controller with 3 drive controllers, expandable to 12 axes (max. 6 interpolated & 6 handling axes), PC, I/O module, safety circuit with rest state monitoring, power supply unit 48 V / 1000 W | |||

| Operation | Control panel iOP-19-TFT | |||

| Weight (kg) | approx. 590 | approx. 670 | approx. 770 | approx. 820 |

| Software | Windows, WinRemote (optional: ProNC, isy 2.8) | |||

| Connection values | 230V, 16A | 400V, 16A | ||

| Part-no. (Z lift = 210 mm) | 278000 252443 | 278001 252443 | 278002 252443 | 278003 252443 |

| Part-no. (Z lift = 310 mm) | 278000 353443 | 278001 353443 | 278002 353443 | 278003 353443 |

| * without mounted components on the axes ! | ||||